Over 70 Years Of Experience

C-B Tool is 25,000 square foot family-owned Machine Shop that traces its roots back to the War effort of the 1940s. Through 4 generations, we have never wavered from our objective of supplying customers with an American made, quality parts. In 2003 we took our commitment to excellence a step further when we achieved our ISO Certification, which we continue to utilize and improve on to this day. We employ a staff of 23 dedicated and quality oriented employees to meet your manufacturing needs. We meet your needs by being highly cost effective and provide you with quick lead and turn-around times.

At C-B Tool, we maintain very positive relationships with not only our customers, but with foundries/material suppliers, tooling specialists and our outside vendors which consist of heat treaters, platers, painters and powder coaters, enabling us to always provide you with a quality part and one that is delivered on time, as promised.

Learn More About

Our Capabilities

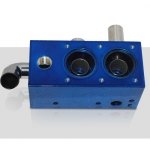

• CNC Machining / Milling & Turning

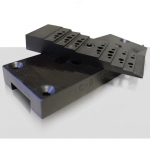

• Welding & Custom Fabrication

Your Product is in Caring, Capable Hands

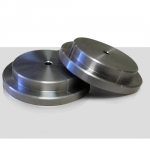

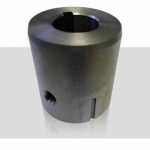

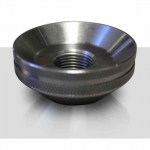

C-B Tool can supply you with machined parts made from numerous types of steels, irons, alloys, aluminum, stainless steel, PVC, soft plastics, brass/bronze, etc. or we will fulfill your needs by machining your own castings or bar stock. We treat all customer supplied materials with the same care that we give our own, and your materials will always be stored inside and out of the elements. Employee safety is also a paramount concern to us, as we have a State Certified Safety Committee that meets monthly to discuss any needs or address issues that may arise on a day to day basis.

We are always looking for ways to machine a better part, which is why we work closely with specialists within the industry and provide on-site training for our operators and programmers when we purchase new equipment. We want to maximize the use of our investments which in turn allows us to keep costs down for you, our customer. We operate two full shifts and we have a very solid scheduling system in place, which gives us the ability to rush and expedite the machining of products, when required.

When your parts are completed, we arrange shipping, be it directly back to you, our customer, or to your customer, as instructed. We can also personally deliver your product with our trucks, when required. When you choose C-B Tool Company for your machining needs, rest assured that we will always work with you from the beginning of the job until its completion, and you will always feel valued and respected by us. We pride ourselves on decades-long relationships with existing customers and suppliers, and we look forward to expanding our ever growing customer base.

View Our List of the Equipment We Use to Make Your Product

CNC Milling & Turning:

(1) Doosan Puma CNC Lathe equipped with Sub Spindle & Live Tooling

(2) Haas VF-4 CNC Vertical Machining Centers

(1) Cincinnati Milacron CNC Lathe

(1) Haas VF-2 CNC Vertical Machining Center

(1) Hyundai Kia CNC Turning Center W/ Auto Bar Feeder

(1) Haas CNC Tool Room Mill

(1) Haas HL-4 CNC Lathe

(1) Milltronics CNC Vertical Machining Center with 50 Taper Spindle

(1) Haas SL-10 CNC Lathe

(2) Haas CNC 4th Axis Rotary/Indexing Tables

(1) Planotec CNC Surface Grinder

(1) Hansford Davis Automatic Keyway Cutting Machine

Automatic Chucking Machines:

(2) Warner & Swasey Automatic Chucker Machines

Multiple Spindle Automatic Screw Machines:

(2) 2 ¼” Capacity Warner & Swasey Five Spindle Automatic Bar Machines

(1) 5 Spindle Warner & Swasey 6” Chuck Capacity

Lathes:

(10) Warner & Swasey Turret Lathes

Grinding Equipment:

(1) Brown & Sharpe Tool And Cutter Grinder

(1) Delta Carbide Tool Grinder

(1) Cincinnati Milcron Tool Grinder

(1) Darex Drill Sharpener

(1) Oliver Instrument Co. Drill Sharpener

(1) Cincinnati Tool Grinder

(1) Radius Grinder

SAWING MACHINES:

(1) Cosen CNC Automatic Saw

(1) Do-All Band Saw

(1) Dewalt Cutoff Saw

Drilling & Tapping Equipment:

(32) Single & Multi Spindle Drill Presses

(2) Bellows Lead Screw Tapping Machines

Welding & Fabrication Equipment:

(1) Lincoln Electric MIG Welder

(1) Lincoln Electric TIG Welder

(1) Lincoln Electric Stick Welder

(1) ESAB Plasma Cutter

Oxygen/Acetylene Cutting Torch

Milling Machines:

(1) Kearney & Trecker Milling Machine

(1) Nichols Milling Machine

(1) Bridgeport Mill

(1) Maxmill With Digital Readout & Bridgeport Broaching Attachment

(1) Kearney & Trecker Horizontal & Boring Mill

(1) Kearney & Trecker Horizontal & Vertical Mill

(1) Cincinnati Horizontal Milling Machine

Miscellaneous Production Equipment:

(1) Porter Cable Wet-Dry Grinder

(1) Sunnen Automatic Honing Machine

(2) Enerpac Hydraulic Presses – 25 Ton Capacity

(1) G.T. Schmitt Roller Marking Machine

(1) Magnus-Magna Lift Degreaser

(1) Vibro-Churn Tumbler

(3) Harrington 1/2 Ton Overhead Hoists

Miscellaneous

(1) Zebra Bar Code Label Printer

(1) Stratix Xaminer Bar Code Reader